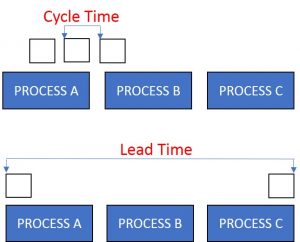

Difference between Cycle Time, Value Adding Time and Lead Time

What are the differences between Cycle Time, Value Added Time and Lead Time? Beginners in lean manufacturing often get confused with the terms Cycle Time, Value Added Time, and Lead Time. In this article, we explain these terms for easy understanding. Cycle Time The time between two successive outputs from a machine or an operation. […]

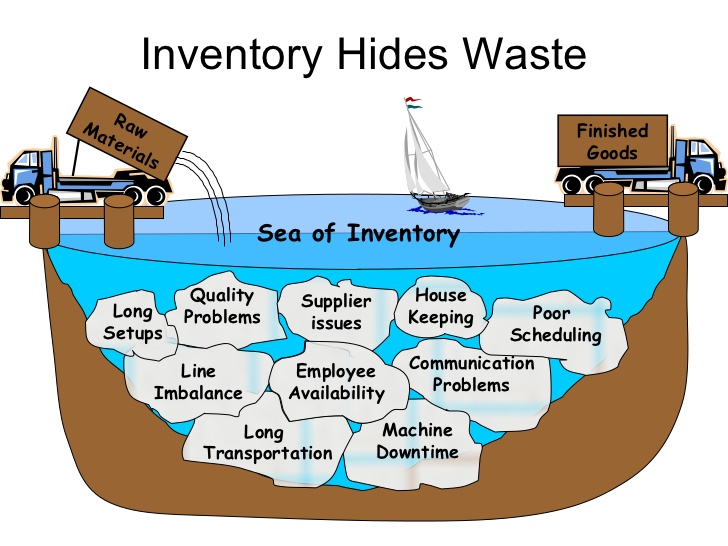

Why Inventory is bad to your company?

Why inventory is bad to your company? Inventory includes all the stock that is present inside the company. i.e. Raw Materials(RM), Work-in-Progress (WIP) and Finished Goods(FG) that are considered to be the portion of a business’s assets. According to Lean Philosophy, Inventory is considered to be one of the 7 wastes in any factory. How […]

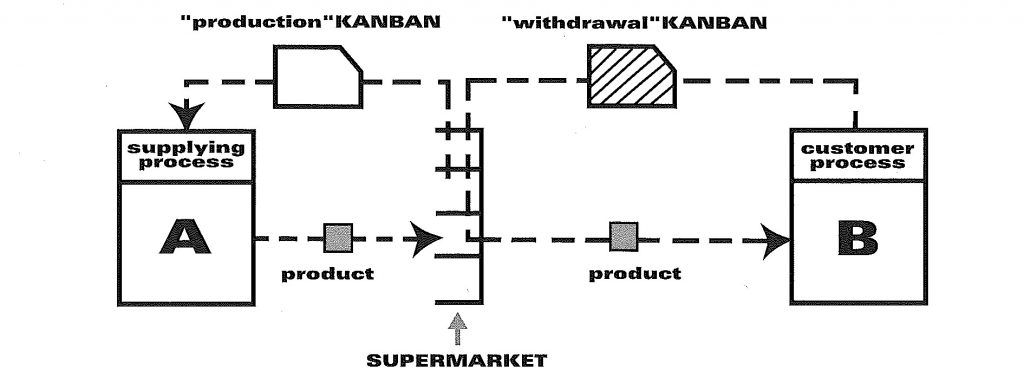

8 Key questions for drawing a future state value stream

8 Key questions for drawing a future state value stream The objective of VSM is to highlight sources of waste and eliminate them by implementing a future state value stream. Based on your answers, mark your future state ideas and then you can draw a future-state map with the same set of symbols used for current state […]

Six steps to avoid overproduction in your shop floor

Six steps to avoid overproduction in your shop floor If you are a person who is wondering why you need to avoid overproduction in the first place, then there is an another piece of article you need to read before going through this one – 5 reasons why overproduction is harmful. In lean manufacturing we try to get […]