What are the differences between Cycle Time, Value Added Time and Lead Time?

Beginners in lean manufacturing often get confused with the terms Cycle Time, Value Added Time, and Lead Time. In this article, we explain these terms for easy understanding.

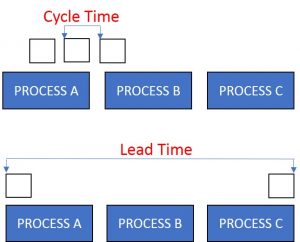

Cycle Time

The time between two successive outputs from a machine or an operation. Normally in lean exercise, we observe 5 to 10 cycles to calculate the average of the cycle times. i.e. take the overall time for completing 10 products and divide it by 10 to arrive at the average cycle time per piece.

Value Adding Time

Cycle time consists of Value Added time and Non-Value Added time (like loading, unloading, etc). Value-added time is the time taken during any physical or chemical change in the product. Whenever there is no change in the product physically or chemically, it is considered under Non-Value added time.

Lead Time

The total time for a product to complete the entire value stream from start to finish. Suppose that the product goes through a continuous flow of operations, then we can say lead time is the sum of all cycle time of each stage of the process that makes a product.

Contact us for a consultation on how Hash LLP can help your business with Lean Manufacturing.

+91 9176613965

Join 3500+ Professionals who receive our Weekly Newsletter containing Simple and Practical ideas to help achieve Results in their companies.

Hash Management Services LLP, 2023 © All Rights Reserved