Lean Manufacturing is a systematic approach to identifying and eliminating waste (non-value-added activities) through continual improvement by creating flow of the product or service at the pull of the customer.

In simple words, Lean Manufacturing is all about Eliminating Wastes. Wastes are the activities that do not transform or change the product Physically or Chemically. There are 3 categories of wastes.

Non-Value Adding Activities

Process Variations leading to inconsistencies of the product / variations in the product

Fatigue to people leading to reduced productivity (Lifting heavy objects / Poor Working conditions)

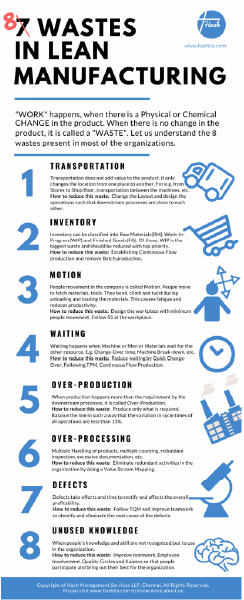

According to Lean manufacturing, there are 7 types of wastes in any manufacturing company. They are:

Explanation – Transportation is any movement of materials from one place to another. This is considered as a waste since it does not change the product physically or chemically, meeting the customer requirement. Transportation cannot be completely eliminated, but “unnecessary” transportation can be eliminated. In general, transportation can be reduced.

How to identify it?

Solution – Transportation waste can be reduced by removing temporary storage locations that cause excessive transportation. Establshing Continuous Flow production where the downstream processes are close to each other also reduces transportation.

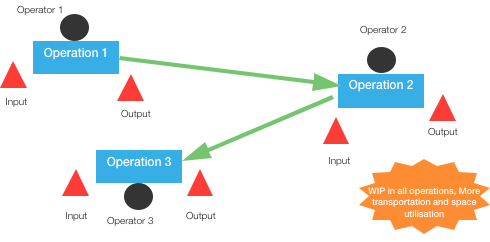

Explanation – Stock tied up in Raw Material, Work-In-Progress (WIP) or Finished Goods is called Inventory and while storage there is no value addition in the product, So Inventory is treated as a waste. Excess Inventory locks up the capital and space. It also requires efforts and time to retrieve and may cause damages during storage and transit. So, Inventory should be maintained in the optimum levels.

How to identify it?

Solution- Inventory(WIP) hides many of the other inefficiencies in your systems – process defects, poor machine utilization, high setup time and poor purchasing processes. Reducing inventory brings all these inefficiencies to the surface, so that they can be solved.

Our suggestion is to concentrate on reducing the work-in-progress. Raw material purchase and finished goods stock generally dependson market fluctuations, seasonality in customer demand, availability of raw materials and commodity price movement and many other factors. So focusing on reducing WIP is a good way to reduce a lot of wastes.

Explanation– Any unnecessary movement of people thatdonot add value to the product is a waste. All of these wasteful motion costs time (money) and cause stress on your employees and machines.

How to identify it?

Solution- Easy access to materials and an efficient work cell design can eliminate these unnecessary motions of operators. Follow 5S to improve the workplace(Set In Order).

Explanation – Imagine we have 3 resources for manufacturing; Material, machine and People. Waiting happens one of these resources wait for the other 2 resources. While waiting there is no value addition in the product.

How to identify it?

Solution – Line Balancing to make sure that all the operations have less variation in cycle times, Creating cells where 1 operator can work on more than 1 machine, Reucing the Change-over time through SMED and break-downs by following TPM.

Explanation – Over processing is putting more efforts / processing into the product than the customer is paying for. All these activities costsmoney and time and hence it is an obviouswaste to be avoided.

How to identify it?

Solution- In most cases, this waste occurs due to lack of correct customer requirements. The objective is to perform only the level of processing that is required to match what is useful and necessary to meet the customer requirements. Improving communication between the teams would also reduce this waste.

Explanation – Producing more than the customer’s requirement is Over-Production. Customer here refers to Internal and External Customers. All the operations must produce only the quantity required in the downstream processes.

How to identify it?

Solution – Establishing Continuous Flow and eliminating Batch Processing is the key solution to reduce over-production. Using tools like SMED, TPM and Pull system, Over Production can be reduced.

Explanation – Producing products that do not meet the customer requirement. It is an obvious waste leading to rework/scrap – costing you time, effort and customer satisfaction.

How to identify it?

Solution – Defects should be prevented from arising at the first place. If there are defects, take Corrective and Preventive Action so that the defects are not arising in the future. Poka Yoke / Mistake Proofing can be used to reduce defects.

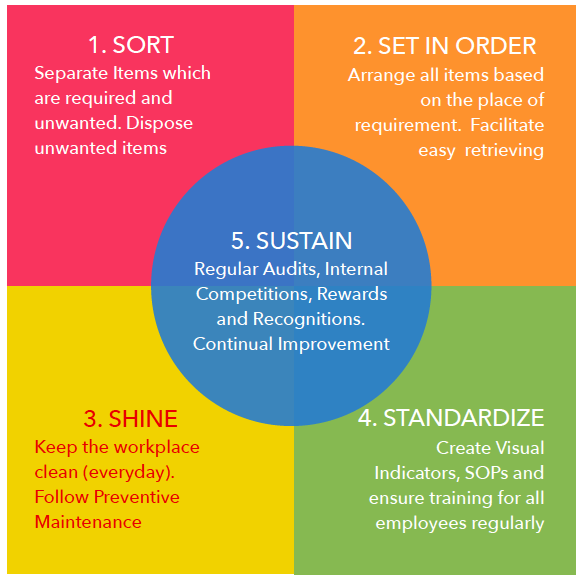

5S is one of the most important tool in Lean Implementation. 5S is the foundation to all improvements

Separate items which are required and not required. Dispose of the items which are not required

Arrange all the required items based on the place of requirement. “A place for everything and everything in its place”

Clean your machines, workplace daily. Follow a cleaning schedule. Follow Preventive Maintenance for machines

Ensure all the above 3 steps are followed by all the employees in the company. Create Visual Indications, SOPs so that the best practices don’t slip back to original condition.

5S becomes a culture of the organization. Regular audits, training, competitions, rewards and recognitions ensure that 5S sustains in the organization. There is no end to 5S and has to be a part of continual improvement

In a machine based operation, if the changeover time / set-up time from one article to another is high (e.g. 2 hours), then the machine’s availability is affected by 2 hours. i.e. machine cannot produce for 2 hours. If the set-up can be done in 15 minutes, then the machine can produce for an extra 1 hour and 45 mins. If the change over / Set-up can be completed in 1 minute, then the machine can be placed in the line (Single Piece Flow can be implemented)

So, how can we reduce the Change Over / Set-up time in machines? We analyse the set-up time, break them into smaller activities, classify them into Internal and External Activities and do 5S in SMED activities, so as to reduce the set-up time.

Internal Activity – Activities that are done inside the machine / can be done while the machine is idle/switched off. e.g. Replacing the punch and die in the machine

External Activity – Activities that can be done outside the machine / while the machine is running – e.g. Getting the tools ready, Cleaning the tools, Preheating the raw material, etc.

Producing in Batches lead to high Work In Progress (WIP)

Join 3500+ Professionals who receive our Weekly Newsletter containing Simple and Practical ideas to help achieve Results in their companies.

Hash Management Services LLP, 2023 © All Rights Reserved