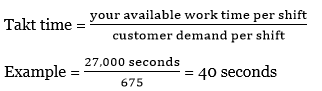

How to calculate Takt Time?

Takt time is a reference number that is used to match the rate of production in a manufacturing process to the rate of sales. It is used to help synchronize pace of production with the pace of sales. ‘Takt’ is a German word for a pace or beat.

In other terms, the customer is buying this product at a rate of one every 40 seconds. This represents the ‘beat’ of the market.

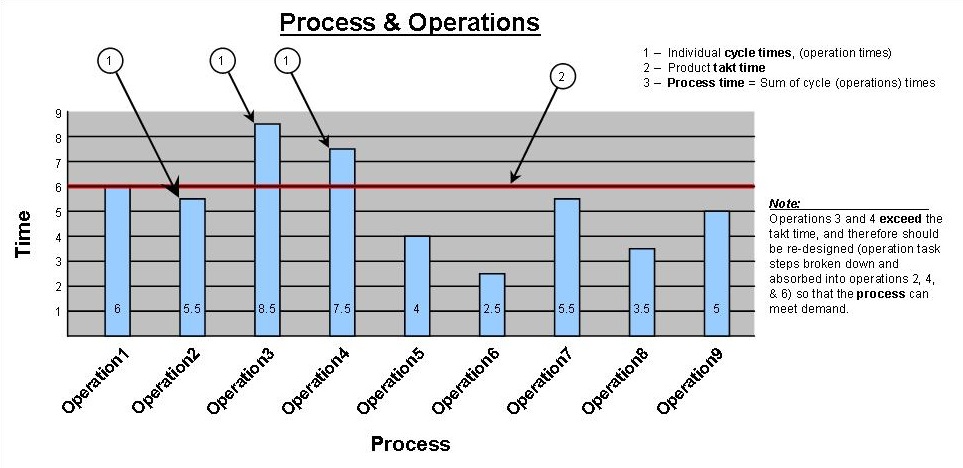

Since the point of takt time is to pace the actual production, the most sensible thing to do is to note down the cycle time of all the different operations in the process and find where each operation stand in relation with the takt time of the product as shown below.

While calculating the takt time it is crucial to identify the ‘effective working time’ per shift. This is start-to-stop shift time minus any scheduled operator breaks, meetings, cleanups, etc. Don’t subtract unplanned machine downtime, changeovers, or other internal problems.

Lastly, the amount of variation in the customer demand can significantly impact the takt time calculations. For occasional spikes, it is generally better to operate at a steady takt time and hold buffer stock of the finished goods. Changing takt time from day to day is inefficient, disrupts the work pace, and increases the potential for quality problems.

To learn more about production management please contact us.

Contact us for a consultation on how Hash LLP can help your business with Lean Manufacturing.

+91 9176613965

Join 3500+ Professionals who receive our Weekly Newsletter containing Simple and Practical ideas to help achieve Results in their companies.

Hash Management Services LLP, 2023 © All Rights Reserved