Muda, Mura & Muri

As a part of the Weekly Lean blog series we have learned about the What is Work & Wastes according to Lean Manufacturing in last week’s blog, this week we will learn about the Lean Wastes/ 3M’s(MUDA, MURA & MURI).

What are the Lean Wastes

In Lean manufacturing, Wastes are categorized into three types. The following are the three Lean wastes,

These three Lean wastes are generally called as 3M’s of Lean manufacturing or Three Lean wastes.

Muda (In Japanese) = Waste

MUDA refers to wastes in most basic sense, any action that doesn’t add value to a product. In simple words, Any Non Value Adding(NVA) activity is termed as MUDA. In the stamping operation example, the waiting time is Muda.

MUDA is further classified into Seven types/wastes. It can be easily remembered with the acronym TIMWOOD (the first letters of the seven wastes).

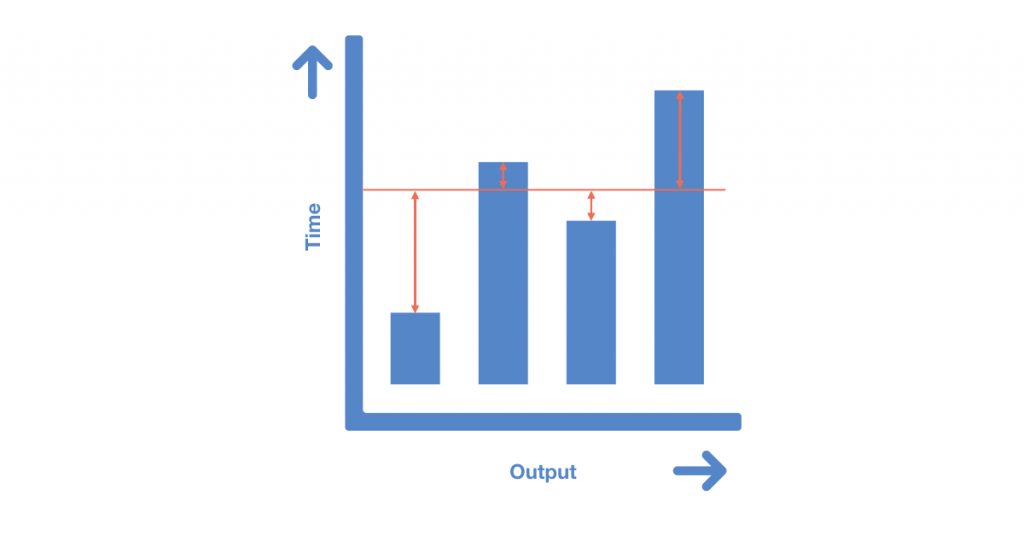

MURA is defined as the Process Variations or Unevenness. In other words, it is the variation of output from a certain operation or process.

For example, in some companies,

Eliminating MURA in any process is very important, since it creates both MUDA & MURI

MURI is the consistent overburdening of Machines or Man. It is pushing a Man or Machine beyond their natural limit, causing Fatigue and Stress increasing the likelihood of breakdown, increased defects or even accident.

For example, Overheating of a battery in old car leads to breakdown. When humans are stressed to work beyond their limit, it can lead to defects or even worse, can lead to accidents.

Here we are at the end of the sixth blog of the Lean Series. Now we have learnt about What are the 3M/ three Lean wastes, Next week we will learn about the Seven wastes in detail

It is so important to introduce Lean Manufacturing in your company and where can we use the Lean Philosophy to reduce the wastes and improve productivity, If you want to implement Lean in your company contact us.

Subscribe to our Newsletters for receiving updates about our Weekly blogs.

Contact us for a consultation on how Hash LLP can help your business with Lean Manufacturing.

+91 9176613965

Join 3500+ Professionals who receive our Weekly Newsletter containing Simple and Practical ideas to help achieve Results in their companies.

Hash Management Services LLP, 2023 © All Rights Reserved