Work Vs Waste

As a part of the Weekly Lean blog series we have learned about the 5 common challenges in Implementing Lean Manufacturing in your company in last week’s blog, this week we will learn What is Work? and What is Waste?

To understand Lean Manufacturing, we need to understand Work and Waste. This is one of the most important realisation that is required in Lean Implementation. The foundation of Lean is to eliminate Waste, so it is essential that we identify / differentiate between Work and Waste.

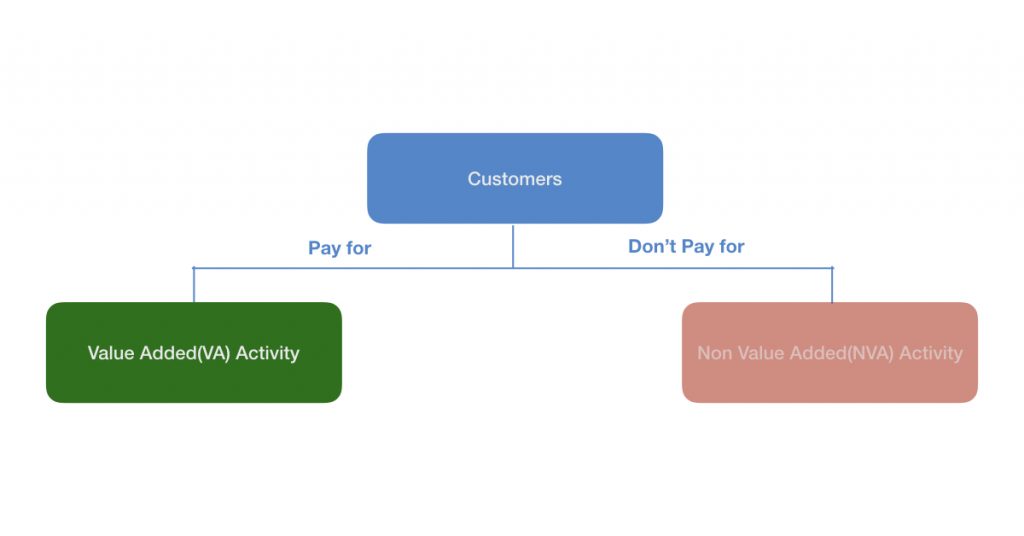

On a broad level, there are two types of activities in a Manufacturing company,

Work (Value Added – VA) – What the customers pay for

Waste (Non-Value Added – NVA) – what the customers do not pay for

What is Work?

A Process that physically or chemically transforms / changes / shapes a product or service which is eventually sold to a customer. In other words, the activities which increase the value of a product is called Value Added (VA) activity for which the customer will be willing to pay for.

What is Waste?

A Process that takes time, resources, space and effort but does not add any value to the product or service, for which the customer will not be willing to pay eventually affecting the profit margin of the company. NVAs are also called as Wastes.

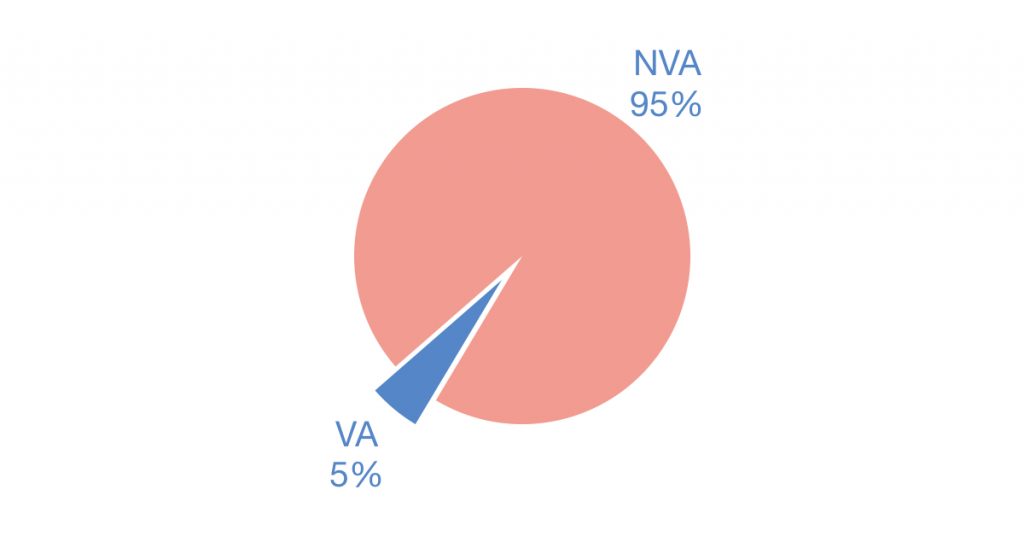

All companies have NVAs, Studies show that in a typical manufacturing unit, VA time constitutes to less than 5% of the total lead time. We cannot eliminate all the NVAs, some of them can be eliminated and many of them can be reduced.

Example: Consider a Batch production situation in a Stamping operation (Batch size 1000 pieces)

Here we are at the end of the Fifth blog of the Lean Series. Now we have learned about What is work and Waste according to Lean Manufacturing, Next week we will learn about What are the three wastes(3M) of Lean Manufacturing.

It is so important to introduce Lean Manufacturing in your company and where can we use the Lean Philosophy to reduce the wastes and improve productivity, If you want to implement Lean in your company contact us.

Subscribe to our Newsletters for receiving updates about our Weekly blogs.

Contact us for a consultation on how Hash LLP can help your business with Lean Manufacturing.

+91 9176613965

Join 3500+ Professionals who receive our Weekly Newsletter containing Simple and Practical ideas to help achieve Results in their companies.

Hash Management Services LLP, 2023 © All Rights Reserved