What is Paper Kaizen?

What is Paper Kaizen? Paper kaizen is a continuous improvement process which describes a process on a paper, used to identify and eliminate/ reduce the waste (Non Value Adding Activities) in the process and thereby streamline the entire process. Every process consists of a set of work elements that will be value adding or non […]

Work and Waste in Lean Manufacturing

Work and Waste in Lean Manufacturing https://www.youtube.com/watch?v=txNgJBc1Pmg Video 3: In this video I speak about the difference between “Work” and “Waste” in the lean manufacturing philosophy. Work: Any activity that brings a physical or chemical change in the product is called work. e.g. In a turning operation, work happens when the tool touches the component […]

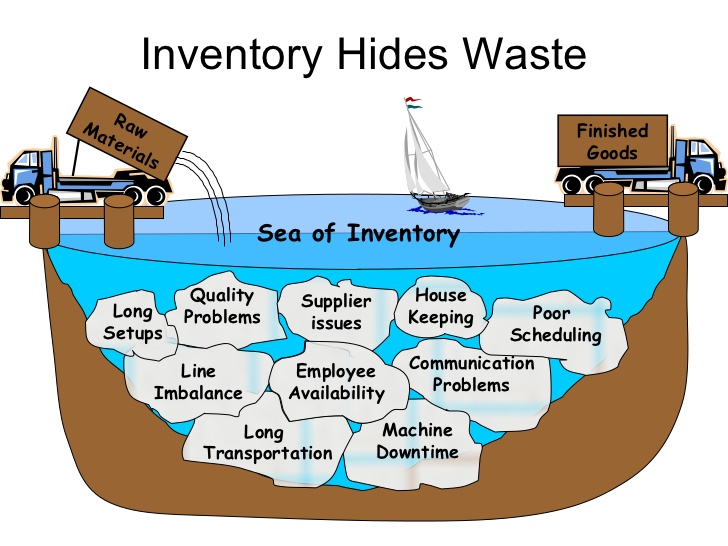

Why Inventory is bad to your company?

Why inventory is bad to your company? Inventory includes all the stock that is present inside the company. i.e. Raw Materials(RM), Work-in-Progress (WIP) and Finished Goods(FG) that are considered to be the portion of a business’s assets. According to Lean Philosophy, Inventory is considered to be one of the 7 wastes in any factory. How […]

The Eight Pillars of TPM

The Eight Pillars of TPM Total Productive Maintenance (TPM) is a set of strategic initiatives focusing on maintaining and improving production and quality systems through the machines, equipment, processes and employees that add value to an organization. TPM has eight pillars that are mainly aimed at proactively improving the reliability of machines. People are at […]